Uma kuziwa kumazinga okusebenza kwesistimu yesixhumi sikagesi sezimoto, okuwukuthi ukuthobelana nezinga le-USCAR-20, isixhumi sezimoto se-USCAR-20 kufanele siphephe futhi sithembeke kuwo wonke umjikelezo wempilo, ukuze kunikezwe abasebenzisi ukusebenza kokuphepha okuyisisekelo.Ngokuthuthuka kwemoto ngokuya ngokusebenza okuningi, okuhlakaniphile, ukuklanywa kwesixhumi semoto nakho kubhekene nobunzima obukhulu, ngakho-ke isixhumi semoto esivivinyweni sophawu, kufanele siphumelele ukuhlolwa kwezimpawu ezihambisanayo ukuze kudlule, khona-ke uyazi ukuthi yini ukuhlolwa kwe-seal yesixhumi semoto?

Ingxenye1.Ukuhlolwa kokuvala

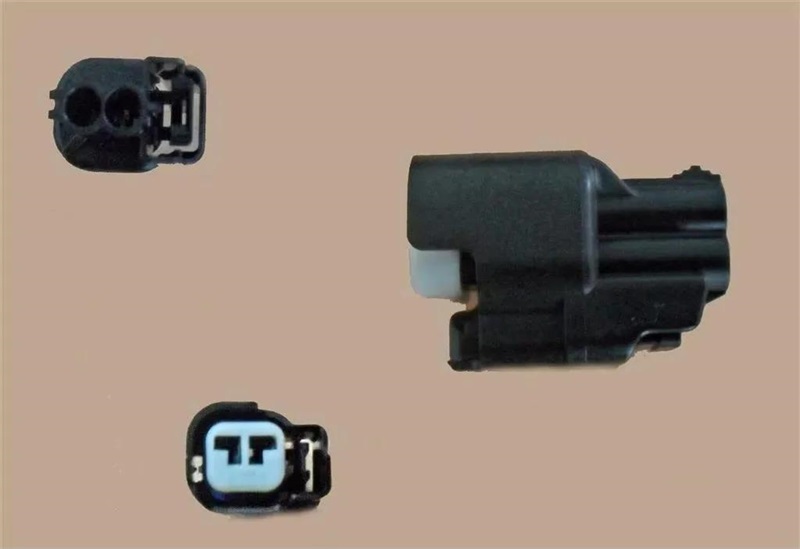

Kudingeka ukuhlola ukuqina kwesixhumi ngaphansi kwe-vacuum noma ingcindezi enhle.Ngokuvamile, kuyadingeka ukuthi uvale umkhiqizo nge-fixture ngaphansi kwengcindezi eyakhayo noma ingcindezi engemihle ka-10kPa ukuya ku-50kPa.Imikhiqizo yokuhlola enesilinganiso sokuvuza esingaphansi kuka-1cc/min noma enesidingo esiphezulu esingaphansi kuka-0.5cc/min iyimikhiqizo efanelekayo.

Ingxenye2.Ukuhlolwa kwengcindezi

Ukuhlolwa kwengcindezi kungahlukaniswa kube ukuhlolwa kwengcindezi engalungile kanye nokuhlolwa kwengcindezi eqondile.Ukuhlolwa kudinga ukukhethwa kwesethi yevalvu yokulawula enembile enembile, kusukela enanini lokuqala le-vacuum engu-0 ngokuvumelana nesilinganiso esithile sokuvala ukuze kukhishwe umkhiqizo, isikhathi se-vacuum kanye ne-vacuum degree yengxenye yezidingo ingalungiswa.Isibonelo, setha i-vacuum extraction ibe -50kPa futhi izinga lokukhipha ngu-10kPa/min.Ubunzima kulokhu kuhlolwa ukuthi umhloli wokuqina noma umtshina ovuzayo uyadingeka ukuze ukwazi ukusetha ingcindezi yokuqala yokukhishwa kwevelu yokucindezela okungekuhle, njengokusuka ku-0, vele, kungadingeka futhi ukuthi kuqale ku -10kPa. , kanye nesilinganiso sokukhipha singasethwa, futhi singashintshwa.Njengoba sonke sazi, umhloli wokufaka uphawu noma umtshina wokuqina komoya ufakwe i-valve elawula ukucindezela okwenziwa ngesandla noma ye-elekthronikhi, engalungiswa kuphela ngokuya ngengcindezi ebekiwe.Ingcindezi yokuqala iqale ku-zero, ikhono le-vacuum elikhiqizwa umthombo we-vacuum (i-vacuum generator noma iphampu ye-vacuum), i-vacuum ngemva komthombo we-vacuum nge-valve elawula ingcindezi imisiwe, isivinini sokukhishwa kwengcindezi esheshayo sisuka ku-0 siye kungcindezi engaguquki. isilawuli set ingcindezi, abanalo ukulawula ingcindezi isizinda kanye nekhono isikhathi zibe izilinganiso ezahlukene.Isimiso sokumelana nokuhlolwa kwengcindezi eqondile siyafana nesokuvivinywa kwengcindezi engemihle, okungukuthi, ingcindezi yokuqala evumayo isethwe kunoma iyiphi ingcindezi, njengokucindezela okungu-0 noma okungu-10kPa.I-slope yokunyuka kwengcindezi, okungukuthi i-slope, ingasethwa, njenge-10kPa / min: ukuhlolwa kudinga ukuthi ukunyuka kwengcindezi kungalungiswa ngokulingana nesikhathi.

Ingxenye3.Ukuhlolwa kokuqhekeka

Ingahlukaniswa ibe ukuhlolwa kokuqhekeka kwengcindezi engalungile noma ukuhlolwa kokugqashuka kwengcindezi.Umkhiqizo udingeka ukuthi uphuke ngokushesha lapho kukhishwa i-vacuum noma ingcindezi isetshenziswa ebangeni elithile lokucindezela.Ingcindezi ephulayo izorekhodwa.Izinkinga zokuhlola yilezi: ukukhishwa komhloli wokuqina komoya kwezidingo zengcindezi engemihle ukuze kuhlangatshezwane nezidingo zokuhlolwa kwesibili, izinga lokucindezela lingalungiswa, futhi ukuqhuma kwengcindezi kufanele kuqedwe ngaphakathi kwebanga elimisiwe, akukwazi ukweqa ububanzi.Ngamanye amazwi, ukuqhuma ngezansi noma ngaphezulu kwalolu hlu akuhlangabezani nezidingo zokuhlolwa komkhiqizo, futhi ingcindezi yokuhlola yaleli phuzu lokuqhuma kufanele kurekhodwe.Uma ukuhlolwa kwangempela, lokhu kuzimisela kudinga ukuthi kube nedivayisi yokunqanda uthuthuva, idivayisi evamile yokulwa nodlame iwukubeka umsebenzi wokuhlola kusilinda wensimbi engagqwali omelana nokucindezela, ucezu lokusebenzela lokuhlola kudingeka luvalwe, isilinda sensimbi engagqwali yangaphandle. ikhava idinga ukusetha i-valve yokusiza umfutho ophezulu, ukuqinisekisa ukuphepha.Uma kwenzeka ukuqhuma, izingcezu zesixhumi zihlakazeka ngaphakathi kwesilinda sensimbi engenasici, okungeke kubangele ukulimala kubasebenzi.

Kusukela ekuhlaziyweni okungenhla, singabona ukuthi isihloli sokuqina komoya sivame ukudizayina amadivaysi amathathu ahlukene ukuze kuqedelwe ukuhlolwa kokuvuza kokuvala ngokwakha umtshina ovuzayo ngohlelo lokulungisa.Ukuhlolwa kwengcindezi kudinga ukukhuphula isethi yevalvu yokulawula ngokulinganayo, ukusetha okunembayo kwevelu yokucindezela kanye nobudlelwano bokulinganisa besikhathi.Ukuhlolwa kokuphuka kudinga ukuthi umkhiqizo uqhume phakathi kwebanga elithile, kodwa futhi urekhode inani lokuqhuma.Uma lezi zinhlelo ezintathu zihlanganiswa ndawonye, kuwubunjiniyela besistimu obuyinkimbinkimbi.Yiqiniso, lezi zivivinyo ezintathu ngokuvamile zidingeka ukuthi ziqedwe ngokuphelele.Inani lokuqala lokucindezela lingasethwa ngokungafanele, futhi izinga lokunyuka noma ukwehla kwengcindezi lingalungiswa.Uma ingcindezi inyuka noma yehla ibe yinani elithile futhi ifinyelela ebangeni elibekiwe lokuqhuma, umfutho wokuqhuma uzorekhodwa.Uma ingcindezi inyuka noma yehla ibe inani elithile futhi umkhiqizo ungaqhumi, ukuhlolwa kokuvuza kwe-seal kuyenziwa futhi izinga lokuvuza noma ukuguqulwa kwengcindezi ngesikhathi seyunithi ngayinye yokuhlolwa kwe-seal kuyarekhodwa.

Imiphumela yokuhlolwa idinga ukugcinelwa ukulandeleka kwekhwalithi ngemva kokuhlolwa.Yonke idatha yokuhlola iyadingeka ukuze ilandeleke futhi igcinwe futhi ilayishwe ngefomethi edingwa ukuhlolwa ukuze kube lula ukuhlaziya ikhwalithi nokulawulwa kwekhwalithi.Embonini yokubona ukuvuza okuvaliwe, lezi zinkampani zezimoto zaseYurophu naseMelika zinezidingo ezithile zokuhlolwa kokuvuza: ibhakhodi yesiqeshana somsebenzi kufanele iskenwe futhi irekhodwe ngaphambi kokuhlolwa, futhi ibhakhodi kufanele ihambisane nemiphumela ethile yokuhlola efana nosuku. nesikhathi ngemva kokuhlolwa.Ngenhla, yizidingo ezihlobene nokuhlolwa kokuvala isixhumi sezimoto, ngithemba ukukusiza.

Isikhathi sokuthumela: Apr-13-2021