Njengoba sonke sazi, i-Terminal Block iwuhlobo lwesixhumi.Kuhlelo lokuxhuma okuzenzakalelayo kwamandla kagesi, ukubonakala kwe-Terminal Block kungashiwo ukuthi kukhulula izandla zezisebenzi zokunakekela.I-terminal block inezinzuzo zesakhiwo esilula, izinhlobo ezihlukahlukene kanye nesicelo esivumelana nezimo.Ikakhulukazi lapho ukwehluleka esibulalayo, esikhundleni ilula kakhulu, kudingeka kuphela ukususa ngokushesha esigungwini esibi esikhundleni semininingwane efanayo yetheminali entsha kungaba, kakhulu ukunciphisa isikhathi nokugcinwa.Indlela yokuxhuma ye-terminal block ngokuvamile ihlukaniswe yaba izinhlobo ezinhlanu.Nakhu ukukuchaza ngokucophelela.

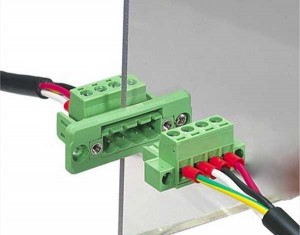

[ Ukuxhuma isikulufu ]

Ukuxhumeka kwesikulufa kuyindlela yokuxhumana yebhulokhi yohlobo lwesikulufu.Kuphakanyiswa ukuthi kufanele unake isigaba esiphezulu nesincane sesiphambano sentambo yokuxhuma evunyelwe kanye namandla amakhulu okusonta ama-screws anezincazelo ezahlukene.

[ Ukushisela ]

Uhlobo oluvame kakhulu lwe-welding yi-nail welding.Into ebaluleke kakhulu ekuxhumekeni kwe-soldering ukuqhubeka kwensimbi phakathi kwezinto ezithintekayo kanye ne-welding surface.Ngakho-ke ku-terminal block, i-terminal ecindezelwe abandayo, ukhiye uwukuthengiselana.Izingubo ezivame kakhulu emikhawulweni edayisiwe yamatheminali amandandatho yithini, isiliva, negolide.Ipheya yokuxhumana yomhlanga inohlobo lokushisela, uhlobo lwe-punching eye welding kanye nohlobo lwe-notched welding: i-pinhole contact pair inohlobo lokubhoboza lwe-arc olunophawu ekugcineni kokushisela.

[ Ingcindezi ]

I-clamping iyindlela esetshenziselwa ukushwabana nokuphambukisa into yensimbi ibe sezingeni elifiswayo kanye nokuxhuma ucingo kupheya yokuxhumana.Ukuxhumana okuhle kwe-crimping kungabangela izinto zensimbi ukuthi zincibilike zigeleze, ukuze ucingo nokuxhumana ku-deformation ye-symmetrical impahla eluhlaza.Lolu hlobo lokuxhuma lufana nokuxhumeka kwe-welding okubandayo, kokubili kungathola amandla amahle wemishini nokuqhubeka kukagesi, kungamelana nemvelo enokhahlo kanye nezidingo.Kulesi sigaba, kunenkolelo evamile ukuthi uxhumano olufanele lwe-crimping lungcono kune-tin welding, ikakhulukazi ezindaweni ezinkulu zamanje zokugeleza kufanele kusetshenziswe isixhumanisi se-crimping.Uma ucindezela, kufanele kukhethwe uthuli olukhethekile lokucindezela noma umshini wokucindezela ozenzakalelayo noma oyi-semi-automatic.Kufanele kusekelwe itheminali ecindezelwe abandayo, ingxenye yocingo olucindezelwe obandayo, ukusetshenziswa okufanele kokuthintana neshubhu lentambo.Qaphela ukuthi uxhumano lwe-crimping luwuxhumo olungunaphakade, ngakho lungasetshenziswa kanye kuphela.

[ ukugoqa ngocingo ]

Ucingo olunesilonda lugoqwe ngokuqondile kukholamu yesilonda sokuxhumana kwe-angular.Uma ucingo lilimele, ucingo luyalinyazwa ngaphansi kwesimo sokuthi ukushuba kulawulwa, bese kucindezelwa kufakwe futhi kugxilwe emaphethelweni nasemakhoneni ekholomu yesilonda sengxenye yokuxhumana, ukuze kwakheke ukuthintana okuqinile emoyeni.Kunezinhlinzeko ezimbalwa zocingo lwesilonda: ububanzi bocingo kufanele bube phakathi kwebanga elingu-0. 25mm~1.Lapho ububanzi be-conductor bungekho ngaphezu kuka-0.5 mm, amandla okuqina wezinto zomqhubi awekho ngaphansi kuka-15%;Amandla okuqina wento yomqhubi akufanele abe ngaphansi kuka-20% lapho ububanzi bomqhubi bungaphezu kuka-0.5 mm.Amathuluzi asongayo ahlanganisa isibhamu esimazombezombe kanye nomshini wokusonga omile.

[ Gcoba ukuxhumana ]

Uxhumano lwamapayipi lubizwa ngokuthi i-insulation displacement connection, lwasungulwa yi-United States ngawo-1960 ubuchwepheshe obusha, obunokwethembeka okuphezulu, izindleko eziphansi, okulula ukusisebenzisa nezinye izici, busetshenziswe kabanzi ezinhlobonhlobo zamabhulokhi ebhodi aphrintiwe, ukucindezela okubandayo. amatheminali, amatheminali amaringi.Ifanele ukuxhunywa kwentambo yeribhoni.Lapho uxhuma, umgodla wekhebula awukhumulwa, kodwa isiphetho esicijile somumo othi “U” wetheminali ethinta umhlanga ibhotshozwa emgodleni wekhebula, ukuze ikhondukta yekhebula ingene kancane kancane emseleni ithinta umhlanga futhi iyaboshelwa, ngaleyo ndlela ikhiqize uxhumano lukagesi olungenakuhlukaniswa phakathi kwekhondakta yekhebula kanye nomhlanga wokugcina.Idinga amathuluzi alula kuphela, kodwa idinga ikhebula eline-gauge yocingo enqunyiwe.

Isikhathi sokuthumela: Apr-21-2021